Xiamen Loadcell Technology Co., Ltd.

Xiamen Loadcell Technology Co.,Ltd.(LCT),was established in 2003, engage in the developing, producing, selling and servicing of strain gauges and load cells. Thanks to the support of our friends and clients, our production capacity has reached 30 million strain gages and 3 million load cells yearly. The strain gauges are commonly used for stress analysis and distortion tests in various industries, also used in the production of load cells; Load cells are mainly used in various electronic scales and industrial control fields.

LCT’s initiator is experienced in the technological research and production of strain gauges and load cells. All of our technicians are craft talent with experience in these areas; Make sure our products have the characteristics of advanced technology and stable performance.

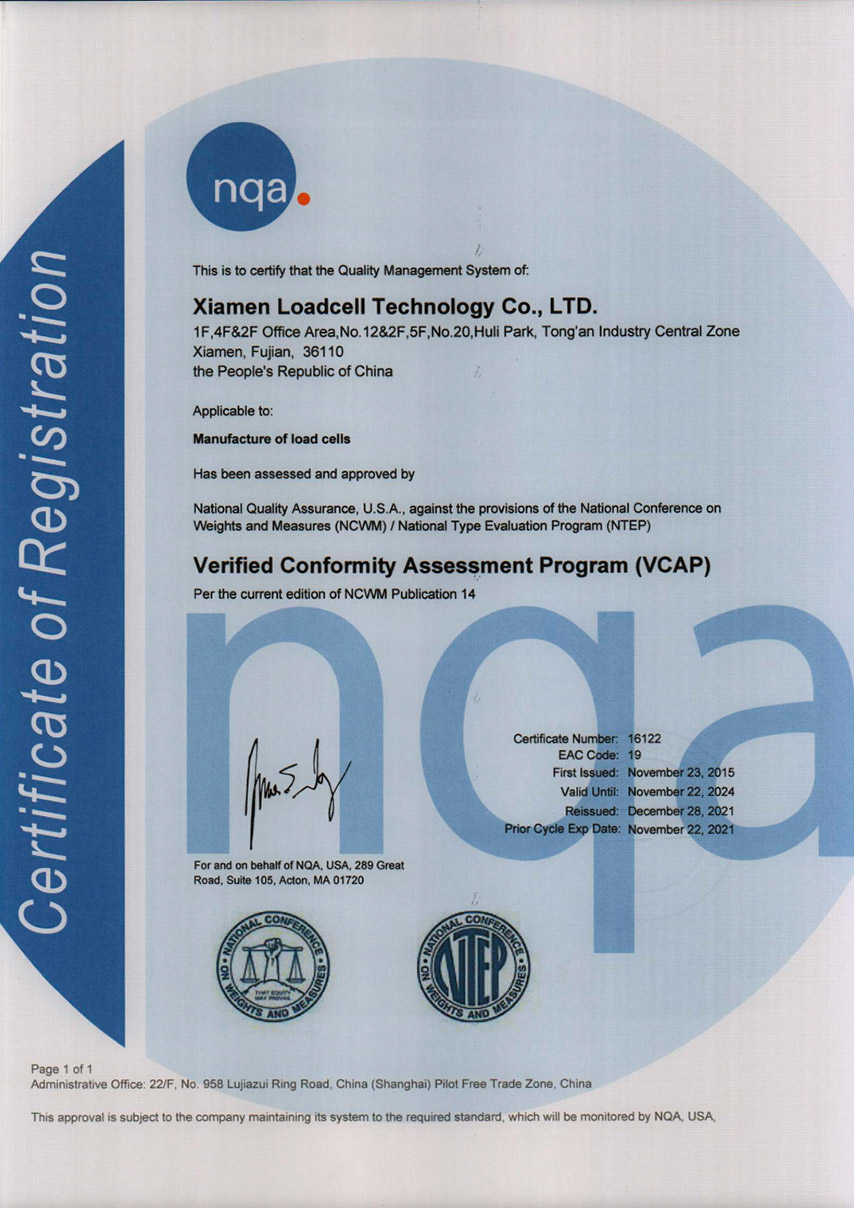

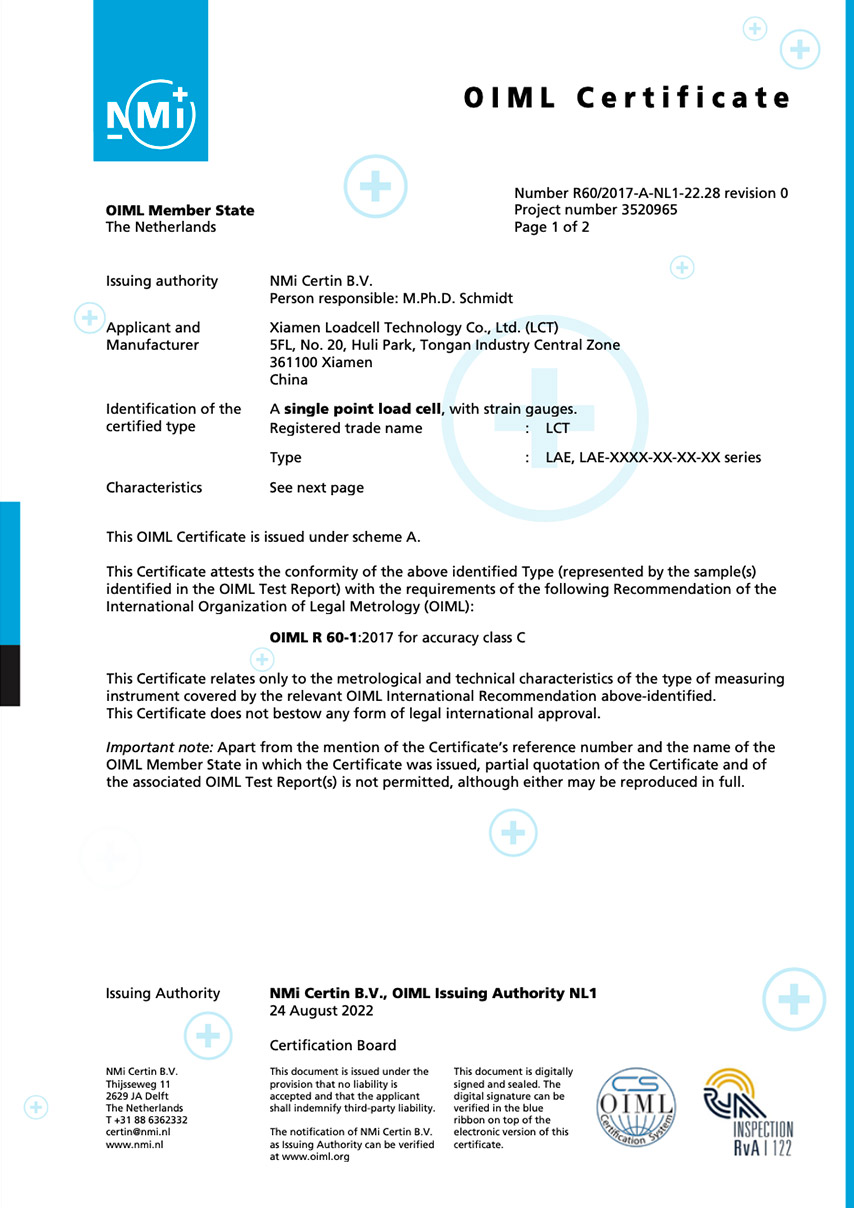

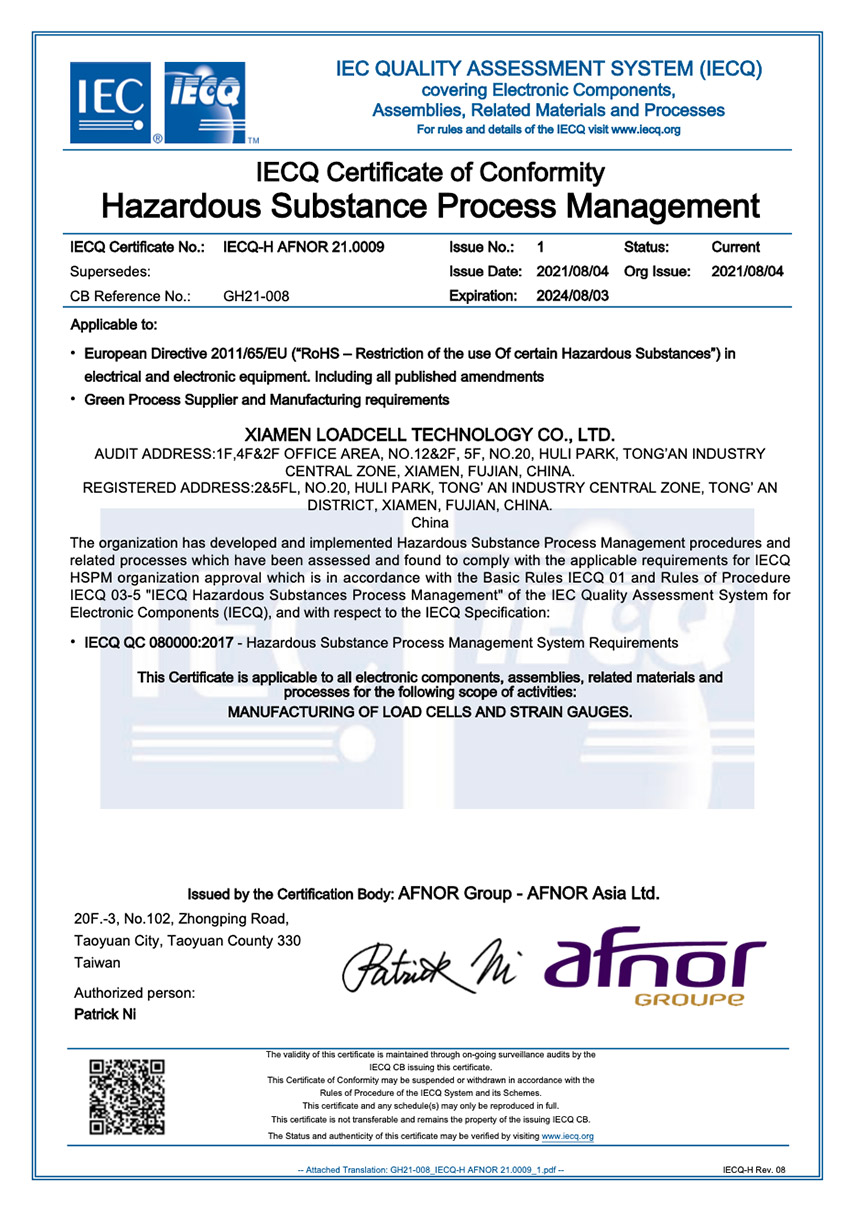

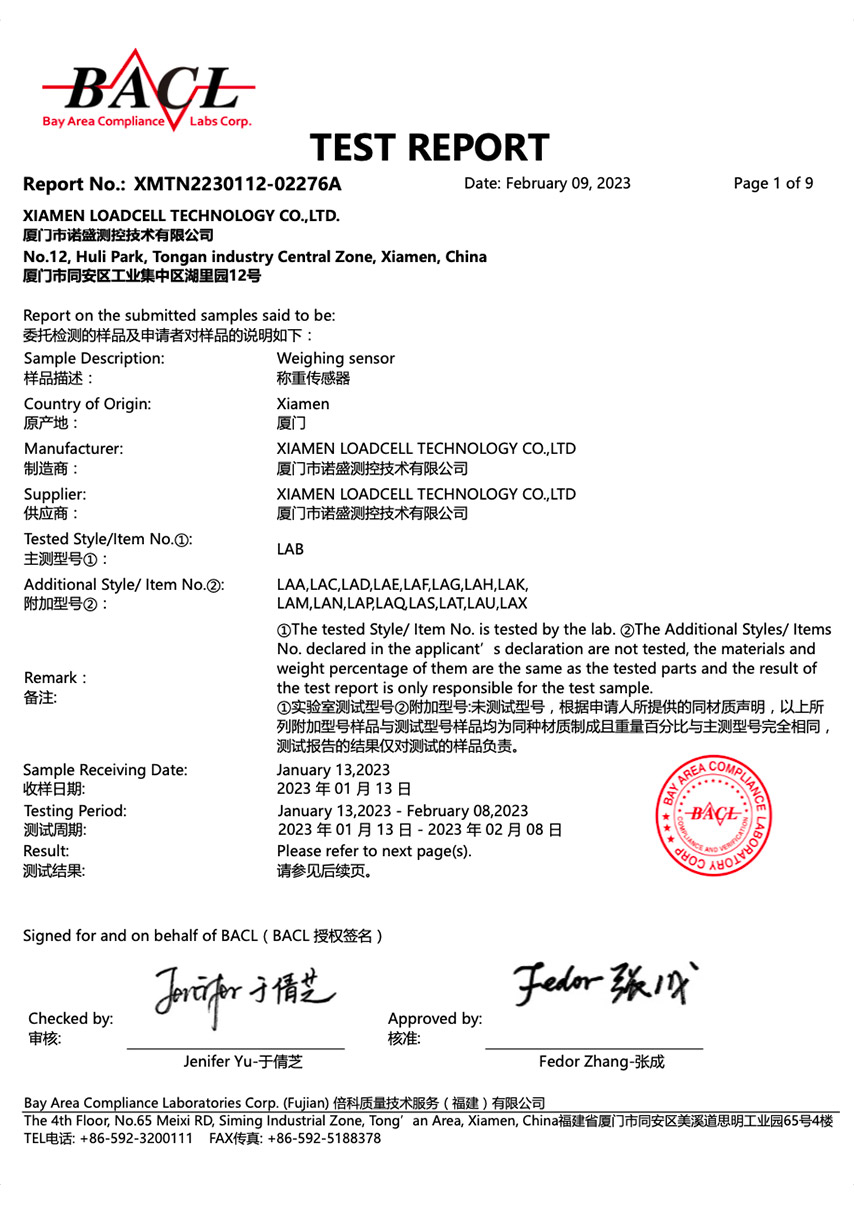

As a result of the serious implementation of modern management mode, we are ISO9001:2015 approved, to make sure the stability of the quality. The products are manufactured strictly according to OIML R62 & OIML R60, and parts of them are OIML R60 approved. Our goal is to provide goods, which can meet the international standard.

We have a professional and active sales team, to provide satisfying service of pre-sales and post-sales. Our objective is to facilitate clients and let them have no worries.

“Innovation and Progressing, Fine Management, Harmonious development, Mutual benefit by cooperation” is the operating idea of LCT, welcome all of our clients and potential clients come to instruct our work, and discuss the development together!

Advantage

Resistance strain gauge

Technical difficulties: materials+processes

● Self developed confidential formula base

● Foil heat treatment process

● Batch consistency control

Load cell

Technical difficulties: high precision+mass production capacity

● Maximum milligram resolution

● Automated mass production

● ISO quality management system

● ERP human+machine+material process control

Customized module

Technical difficulties: R&D capability+traceability control

● Fast and accurate research and development solutions

● Accurate sampling

● Barcode batch+database record control

● Feasibility planning for mass production

Development History

-

At the beginning of its establishment, only resistance strain gauges were produced

-

The new factory covers an area of 1000 square meters and sensors are put into operation.

-

Micro sensors have become a well-known brand and a major supplier in the industry.

-

Settled in the Tong'an Industrial Concentration Zone, with a factory area of 5000 square meters, and passed the ISO9001:2000 quality management system certification in October.

-

Strongly launching high-precision balance and industrial electronic scale series sensors

-

The factory area has increased to 10000 square meters, with an annual production capacity of 5 million units, and is the main supplier of balance manufacturers.

The first product in June passed OIML certification and was recognized by the European Union.

-

We have started independent research and development of automated production equipment to address consistency in large-scale production and improve production efficiency.

Developed the first sensor suitable for smart appliances.

-

The era of the Internet of Things has beckoned to us, and we are ready

-

The brand new CNC elastomer processing workshop ensures production capacity, quality, and steady development.

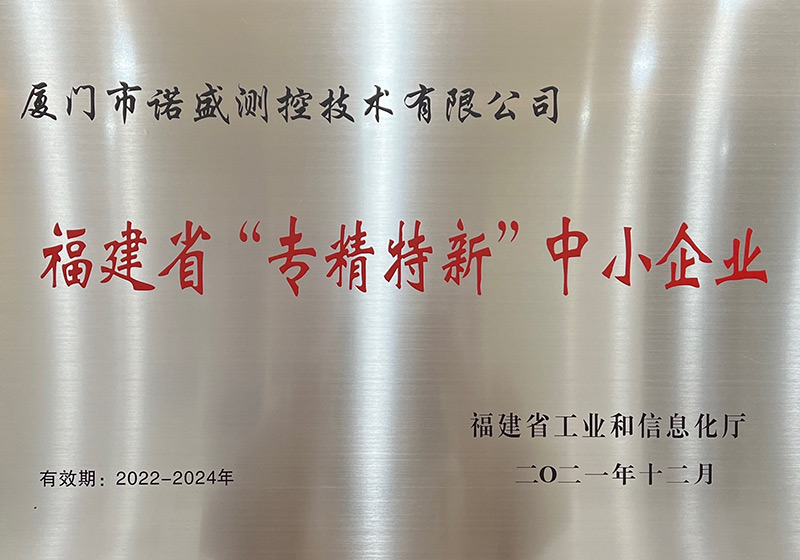

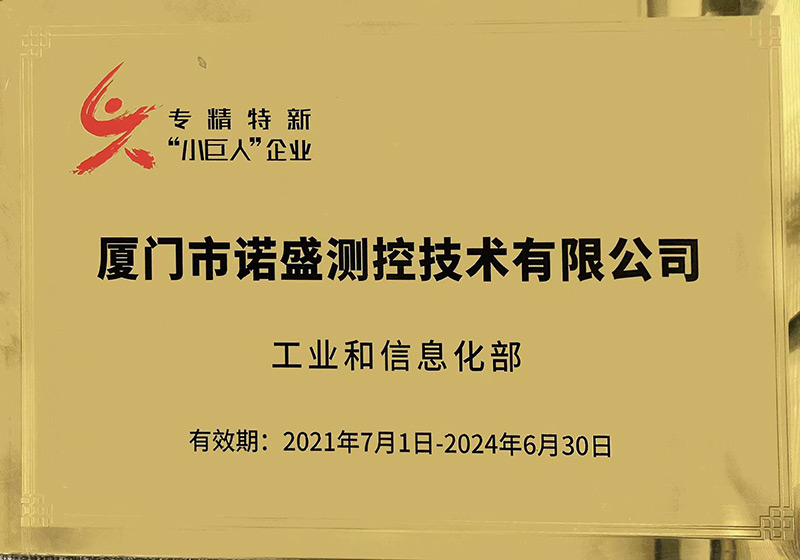

Corporate Honors&Certification